- German breakfast - yeah I missed American breakfast at first, but I'm really missing the great spread of meats, cheeses and breads every morning.

- The autobahn - there's nothing quite like a country that as a principle has no speed limit; there's also nothing like going 210 klicks in a minivan.

- Pulling into a town that has a castle; or an eight hundred year old church.

- The bread, it is absolutely amazing.

- Authentic German food - the variety of pork, sausages and cured meats was a treat as well as the cabbage and potato dishes.

- The beer and schnappes - their beer is heartier than ours and tasting the schnappes is truely an experience I won't soon forget.

- The sights, history and traditions of this great old country.

- The agriculture - this was more eye opening to me; I was expecting much smaller farms (granted we we're in the larger farming regions of Germany); we noted several times that there was as much difference between our group (Ohio, Oregon and Colorado) as there was between the U.S. and Germany.

- The German people, we always felt welcome in their country; and most Germans spoke English very well.

- My new friends - it was a pleasure traveling with such a great group, Tracy, Shane and Katherine. We always found a way to have fun and had some great discussions along the way.

Monday, October 17, 2011

Things I miss from Germany

Friday, October 14, 2011

Day 20 - Friday, October 14

The last day of farm tours took us first to a farm that grows sugar beets as well as seed for other farmers. They have 205 hectacres (62 ha sugar beets, 103 ha winter wheat, 21 ha winter barley, 13 ha summer barley and 6 ha set aside). Their sugar beet production is much larger than other farms in the area that are typically 10 hectacres. They farm about 100 km from the sugar beet processing plant and have a unique system for harvesting. They share a harvester that is owned by the processor, with 40 other farmers. Their "turn" to harvest is determined in the the spring so they know exactly when they will be harvesting beets. The farm is located inside the city limits of Frankfurt Main; it is all rented land from foundations that had been established centuries ago; the family is the 6th generation on the land. They produce seed for coopeatives to sell to other farmers and own all of the equipment for storing, cleaning and procesing all of the seed on their property. We did a quick walk to one of the fields that had mustard which is used as a cover crop to reduce nematodes on ground that will be sown to sugar beets next year.

They noted that they have a concern with urban growth being so close to a large metropolitian city; but the concern is not with houses, its with the regulations. For example, the airport needs to expand an additional runway, in order for it to grow the airport must also have a biological offset for the amount of land used for the runway. To complicate matters worse the city of Frankfurt has determined that the biological offset must be in Frankfurt, so the by default farm land ends up being taken out of production.

We then were hosted at Rentenbank, a agricultural lender similar to our Farm Credit banks. They were established by law in the late 40s to promote agribusiness and rural areas. The basis for the bank's capital was constibutions paid by the German ag and forestry secotr between 1949 and 1958. Today they are the premier ag lending agency of Germany; they now raise funds globally and distribute them locally. The bank is registered with the U.S. Securities and Exchange Commission (SEC), which then allows them to issue global bonds internationally. Their loans focus on four key areas: agriculture, aquaculture & fisheries, agribusiness and renewable energies. An underlying loan category in all these areas is innovation. They believe stongly in their farmers ideas and use the innovation loans to help move agriculture forward.

They have a unique way they distribute their loans. Rather than having individual banking locations and a staff of loan officers, they utilize their local banks and allow them to write the loans for a commission. This allows the local bank to provide farmers access to low intrest loans and does not put them into a competitive arena with a home bank. Last year they made a net profit of 11.8 million €, half was distributed to a special purpose fund that promoted innovation loans and the other half was put toward a promotional fund that supports individual projects as well as institutions working for the ag sector and rural areas.

We spent the afternoon in Frankfurt walking the city and toured the Goethe House that was the family residence of the Goethe family, most notably Johann Wolfgang von Goethe, until 1795. Goethe is one of the most popular poets of Germany writing The Sorrows of Young Werther (1774) as well as laying the foundations for his celebrated interpretation of Faust.

We ended the evening in a cider pub enjoying a traditional krautwickel, pork wrapped in a cabbage leaf that is cooked and served with a bacon sauce, and trying some apfelwein a traditional German cider well known in Frankfurt.

Thursday, October 13, 2011

Day 19 - Thursday, October 13

We began the morning by visiting only the second pig farm on the trip, we found this a little amusing because when you're in a country that eats as much pork as the Germans you think you might see a few more hog operations. This farm was another family operation that was well diversified in different ag ventures. They had 100 sows and 350 feeder pigs; the sows are only in crates for a short time prior to farrowing and until the pigs are weaned. Other than that they are group housed and have access to the outside; this was a law that was passed by the EU. In the mid 90s, hog prices were at a low, the family decided one way to improve their prices was to begin direct marketing. So, they opened a sausage shop, that included an on farm slaughter and processing facility. They sell a wide varitey of home made and smoked meats, sausages and wurst; and slaughter a few head a week, selling about 10% directly to consumers. They operate under the same EU standards as a larger processor. In addition to the meats, they also sell locally grown foods, wines, potatoes, jams, pastas and breads.

They also are part of a partnership with two other farmers, sharing equipment on their farm ground. The family has 240 hectacres spread over 85 fields, with the largest being 20 hectacres. In the past, land was divided over and over between heirs, this created separate plots of land. More recently there has been a movement to consolidate these lands, but it takes cooperation with the local community. They grow silage, barley, wheat and potatoes. The partnership is also shared with a biogas plant that uses slurry from the pigs and another farmer's cattle as well as silage and straw.

Following our tour we enjoyed samples of their products, one that tasted very reminiscent of the German sausage my family makes in Iowa.

We stopped briefly in the city of Bad Nauheim, so we could see the home that Elvis lived in when he was stationed in Germany during the war. We also found a memorial at another location where he had stayed. This made Tracy very happy as she is a big Elvis fan.

We then traveled north to meet with their forest service. The forest is important in Germany historically, it provided wood, lumber, charcoal, mushrooms,fruits and the orignal means for raising pigs. Today 30% of Germany is forest (the state of Hessen is 42%), while 200 years ago over use had the forest down to only 10%. Today they have what they call permanent forests, no clear cutting wood, they use a thinning process to harvest trees from the forest. In Hessen 85% of the forest is public owned with 15% held privately; last year they harvested and marketed 120,000 cubic meters for about 7-8 million €. This provides about 85% of the forest budget. The trees are used for: 40% saw mills, 40% paper, industrial and pressed board, and, 20% firewood. The trees are tradionally beech forests, today they are 40% beech, 60% spruce and pine wood. The service is planting more trees from warmer cliamates in fear and preparation of climate change.

We talked some about renewable energy because the Hessen government has required that wind power first be put on forest lands to shield the wind towers from view. We learned about a complicated system that I'm trying to find more information about. It takes approximately half a hectacre for a windmill, this must be compensated by planting new forest or buying ecopoints. An ecopoint, is a forest conversion formula that rates ecological values in the point system. i.e. Because of the volume of wood removed, if you clear cut a half acre for a windmill, you may need to plant 2 acres to equate the volume of young trees with the number of old. It sounded like a system that would routinely eat usable arable land. I found it odd that a wind turbine did not have an equal ecopoint system because it should offset the use of carbon based fuel.

We ended the day walking around Marburg, an old university city and the first protestant university and a site where Martin Luther and others in the reformation began. We walked up a very steep hill on shaky cobblestone; we walked so high up the hill, you could swear you we a little closer to heaven. We dined that evening in Marburg and celebrated our fellow McCloy, Katherine's birthday.

Wednesday, October 12, 2011

Day 18 - Wednesday, October 12

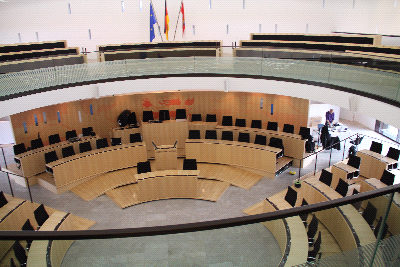

We began this morning with a tour of the Hessischer Landtag, the Hessen capitol building. It was a fantastic tour in a building mixed with old architecture and new. My words can't do justice to describe the pictures below.

The parliament meets in a round chamber with the "left wing" parties sitting on the left, to the more "right wing" parties on the right. It is also a porportional parliament, so the largest party, the Christian Democratic Union (CDU) has a coalition with the Free Democratic Party (FDP). Their system is quite facinating, but its somewhat of a graduate-college level math problem to understand. We met with Klaus Dietz a member of the parliament and someone who is on their ag committee. He grew up on a very small diary farms 30 kilometers away. In Hessen there are many specialized farms; 60% of the agricultural income from is from dairy production followed by pigs, wheat and oilseeds. There are five regions in Hessen that specialize in grain farming, wines, wheat in the northern fertile soils, wood forests to the south, grasslands, dairy farms and some arable land with corn.

Mr. Dietz felt that farmers are more conservative in nature and vote for the CDU about 80% of the time because the CDU believes in personal responsibility and the entrepreneurial spirit. There are 118 members in parliament, five are farmers.

We talked extensively about agriculture and focused on a couple of the topics of the day: energy and the environment. He noted that like the consumer who thinks chocolate milk comes from a brown cow, most consumers think electricity just comes from the wall and at the peak of concern with Fukushima, Germany was nearing their elections. That is why the state parliament moved so quickly to ban nuclear energy. This is forcing energy production from biogas, solar and wind, which have guaranteed prices set by the government. Agriculture is key, especially looking toward the future of wood based biomass from fast growing poplar trees and forest trimmings. He noted that Germany will also need more wind energy; the last time wind energy was pushed there were guaranteed investment loans and price support from the government, today there are only price guarantees, but no additional investment from government. He said that this is being paid by consumers and their prices are rising as well as industrial costs for manufacturing.

We also talked about animal welfare and the challenges of fighting special interests groups who are trying to change agriculture back to 1960's style production. He noted that the EU announced a cage ban for hens in 2001 that would phase out cages by 2008; Germany banned cages immdeiately and is enforcing the law, however the EU ban is not in force yet in other countries and in many circumstances cages are moving from Germany to other EU countries, which is creating an unlevel playing field.

Finally we talked about the state challenges of farm subsidies; payments are split 50% EU, 30% federal and 20% state. The state is in charge of the control system for farmers to receive payments. Last year there were 226 million Euro in direct EU payments to Hessen farmers. He said that the payments fit into two boxes direct patients and environmental subsidies; more and more efforts are being pushed toward the environmental areas. He said his concern is that their country has had 66 years without war, the older generation know it but the young don't appreciate where we've come from. We need agriculture to have sustainable food production, to suceed as a country they must find solutions at the table and not on the battlefield.

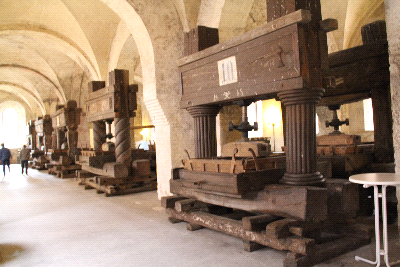

After lunch we drove to the Abbey Eberbach, a former monastery known for its impressive Romanesqueand early Gothic buildings and is considered one of the most significant architectural heritage sites in Hesse, Germany. Additionally, the abbey is known for its outstanding wine production that gave the monks the ability to build other monasteries across Europe. We toured the buildings and had a wine tasting of local Rieslings.

Then we traveled to a horse boarding facility that was very unique. The family farms about 250 total hectacres, but has a boarding facility that encompases 19 of those hectacres with barns, riding arenas and horse pastures. They board about 30 horses but do not have individual stalls, they work on a group system where the horses run together in large paddocks that are rotationally grazed. Additionally, each horse is microchipped for animal identification. They use this ID to trigger and automatic grain system that feeds each horse a precise daily ration. The horse facility is engineered to optimize the exercise for the horses requiring them to visit the feeder in one area, stable in another, pasture in another and water in yet another area. We got into some conversations with some of the boarders at the stable. They said they selected this stable because it allowed their horses to get exercise whether they could ride them or not. We ended the day with a light meal with the family that gave us some time to tell about our farms and ranches in the U.S.

Tuesday, October 11, 2011

Day 17 - Tuesday, October 11

We started at MUH (get it? German Moo...) a farmer owned dairy cooperative founded in 1967. The cooperative consists of 2,600 farmers in a 250 km radius; they get milk from the five countries of Germany, Netherlands, Belgium, France and Luxembourg. The company employes 770 employees and specializes in longlife milk products that are essentially sterilized. They recieve over 1,150 million kg of milk from their farmers. They produce a large number of products, 85% are private labels (i.e. King Soopers branded milk), with the remaining 15% branded as MUH. Their market is 50% UHT (Ultra high temperature milk), 17% evaporated milk, 15% cream and 8% flavored milk.

We then traveled two hours to the Landwirtschaftskammer Rhineland-Pfalz. It is a difficult organization to explain, but is essentially a quasi-governmental organization that is run by a board of 80 farmers to provide educatin on services. They are like our department of agriculture, check-off programs, marketing orders, department of health and extension all rolled into one organization. Members must pay a (tax) per acreage fee, so everyone is required to belong, then a board is elected from district representation and industry intrests. They provide education, landuse planning, inspeciton of wines, vines and plantings. They have promotional programs and recognition programs for their best wines. They also provide classes in food preparation, food safety, economics, assitance with on-farm food certification and assisting with banding small tracts of land into better utilized ground. They have a group that provides weekly market reports for inputs and commodities that is available to all farmers. Many of the services are provided to the landowners for free, however some services are added for a fee.

We the took the train to Frankfurt for the final leg of our trip.

Day 16 - Monday, October 10

We started the day trying to get the van (aka the cracker box) to go over 180 klick/hour on the autobahn, it only happened going down hill. We traveled to a goat farm that milks 240 mother goats to mainly produce cheese. The family farm began milking cows; in 1996 they were faced with a decision to build a larger dairy barn and milk more cows or switch to the goats and focused on cheese. They switched the small 3 x 3 milking parlor to accomodate 20 goats at a time and are not marketing to an organic standard because of the cost. The family raises their goats to produce high quality, not necessicarily high quantity milk and will milk their goats for 5-7 years. Milk goats are seasonal breeders, fortunately this matches up nicely with the market for their cheeses, which is from the spring to the fall when restaurants and tourists are most active.

They produce three types and 20 different kinds of fresh, soft and hard cheese (13 fresh, 8 soft and 2 hard cheeses). It takes 6 liters of goat milk to produce one kilo of fresh cheese, (8.5L - soft, 13L - hard). 30% of the cheese is sold on farm, with 20% direct to restaurants and 50% to distributors. Their main problem is getting rid of the males and cull females. They are trying to develop their own market for the meat by working with a local butcher to make pate and dried sausages; they are also making a specialty canned meat.

After that we traveled to Bitburger brewery, a family owned brewery that was founded in 1817; the current CEO is the 7th generation to work at the brewery. They are the 2nd largest German beer maker (in terms of output), but are first in draught beer on tap with 50,000 restaurants serving their product. They employ 1,000 people at their five different breweries that produce many different beers. They are considered a premium beer priced at 12 € per case. They have to compete against the other national premium brands and cheap beer that doesn't market (6€/case). Bitburger makes 400 million liters sales annually, which is approximately 250 million gallons. 90% of their beer is sold in Germany with 10% exported to the EU and worldwide. They are branching into many new product categories, including lower alcohol beers and mixed-beers (i.e. Beer and cola). They actively use social media and are on Facebook. They find this has been a good marketing tool gleaning 40,000 fans in just one year. They have one staff member responsible for social marketing and are targeting younger people. They also market heavily by sponsoring the German national soccer team.

In Germany annual consumption of beer is 110 liters and consumption is declining. Consumers are citing health concerns as well as crack-down on driving alcohol limits and loss of market share to wine, champagne and mixed drinks. In Germany there are 1,300 breweries in Germany, 600 in Bavaria. They have to abide by the Bavarian purity law of 1516, that limits them to using only the pure ingredients of barley (plus yeast), hops and water.

In the afternoon we visited the family farm of our host Arno Billen at Kaschenbach. Arno is a 6th generation, in a village of approzimately 65 people. He farms 250 hectacres, has a dairy, distillery, biogas plant, solar farm and ag tourism. They are a family operation with his father, uncle, cousin and brother all working on the farm. They have grassland, grow wheat and barley as well as silage for the cattle and biogas plant. His uncle is in charge of the farming operation, his father is in the state parliament, his cousin runs the dairy and his brother runs the distillery. Arno is in charge of the biogas plant, solar farm and a facility they rent for parties and schnappes tastings. The 120 cow dairy also includes 140 heifers and beef cattle, the cattle are milked by two milk-robots; they are getting 3.3 milking per day, average yield of 34 L per cow with an annual yeild of 10,500 L per cow.

In 2000 they added a 110 kw biogas plant and expaned an additional 190 kw in 2004 (300 kw total); it takes 125 hectares of silage to feed the biogas plant. They average between 40-55 ton per hectacre silage. To feed the plant each day it takes, 12,000 kg silage, 1500 kg grass silage and 10,000 kg of manure. The solar collectors were added in 2009, the kilowatt peak is 249 kw; last year they had 980 hours of peak kilowatt output. The solar price is under a 20 year contract with the expenses paid off in 10 years. The farmers who produce renewable energy are paid a flat rate to produce energy of €.40/kw for solar, €.20 for biogas and €.15 for wind energies. Because of the German governments recent restriction on nuclear power they are looking at potential sites for wind energy next.

The schnappes distillery utilizes 320 fruit trees, mostly older trees that are wild growing on the farm. They have many, many different flavors including old apple, raspberry, cherry, William pear and pear. It is nothing like the schnappes we have in America. Arno's brother makes nearly 4,000 bottles per year. The family also has an old barn that they've renovated for parties, receptions and entertaining. It has a tasting room to compliment the distillery. When they first opened the barn in 2007 they had 20 groups utilize it, last year 60 groups rented the barn and they've already held over 60 groups this year.

Arno and his girlfriend Simone hosted us for dinner of wild pork and some schnappes tasting. It was delicious.